These days, there is a lot of talk about global warming, sustainability, and recycling. With those topics also comes a lot of confusion. Thankfully, we can clear things up a bit, including for the definitions of remanufactured vs. refurbished.

Many companies have instituted sustainability programs and encourage recycling. Not only does this include paper recycling, but electronic recycling as well. There are many ways in which the reuse of electronics can have a positive impact on the environment and the economy, but you have to choose the right solution to make it work for your business.

The Difference Between Refurbished and Remanufactured

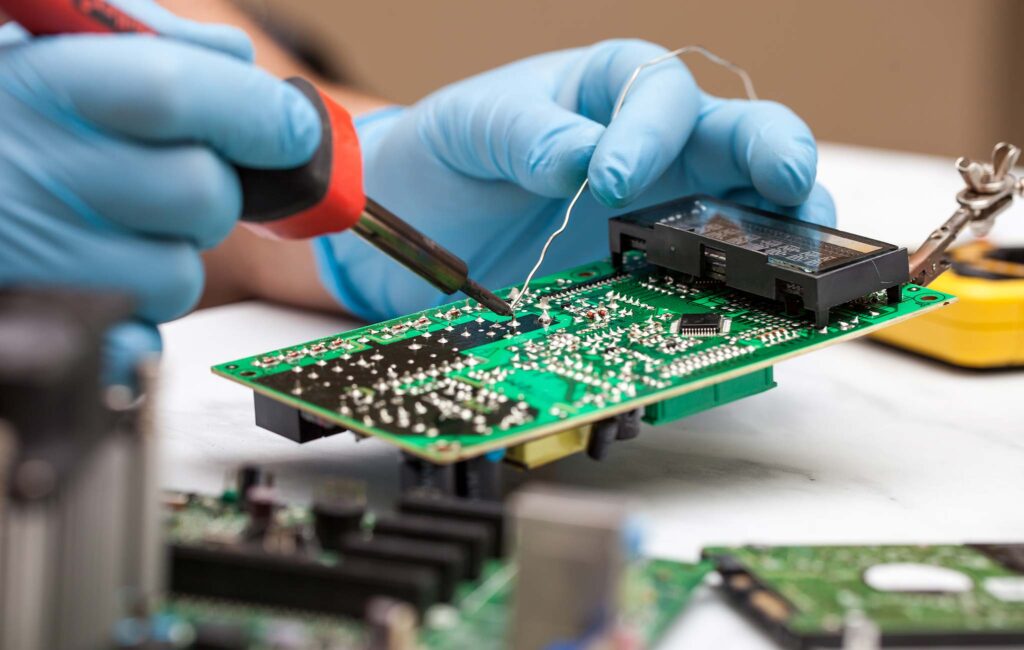

- Remanufacturing is the rebuilding of a product to specifications of the original manufactured product using a combination of reused, repaired and new parts. It requires the repair or replacement of worn out or obsolete components and modules. Parts subject to degradation affecting the performance or the expected life of the whole are replaced.

- Furthermore, remanufacturing is a form of a product recovery process that differs from other recovery processes in its completeness: a remanufactured machine should match the same customer expectation as new machines.

- Refurbishing is the distribution of products, usually electronics and electricals, that have been previously returned to a manufacturer or vendor for various reasons. Refurbished products are normally tested for functionality and defects before they are sold. From there, the product is repaired from the manufacturer and resold.

The main difference between “refurbished” and “used” products is that refurbished products have been tested and verified to function properly, and are thus free of defects, while “used” products may or may not be defective. Refurbished products may be unused customer returns that are essentially “new” items, or they may be defective products that were returned under warranty and resold by the manufacturer after repairing the defects and ensuring proper function.

Another differentiation factor between remanufactured vs. refurbished items is that remanufacturing is a more thorough and costly process because it is more rigorous and works toward a higher standard than refurbishing. If the vendor cannot meet the actual definition of remanufactured (reassembling to meet or exceed the OEM specifications), then it should be considered a refurbished product.

When you choose to either replace, repair or stock electronic equipment, the differences between refurbished and remanufactured make the choice simple. Always choose remanufacturing to ensure the highest quality and to minimize the risk of future problems.

Contact Vecmar Today

When it comes to remanufactured vs. refurbished devices, Vecmar has no shortage of experience with remanufacturing hardware. For over 30 years, Vecmar has specialized in the remanufacturing of devices, accessories, and related products.